NUCOIL WIRE FORMING MACHINE

WHAT IS NUCOIL WIRE FORMING MACHINE?

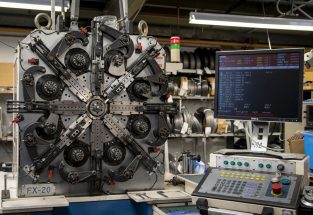

The HX-series spring former is the most technologically advanced and powerful machine accessible today, utilizing the new optical servo motion control and sophisticated Windows-based applications built by NuCoil.

PRINCIPLE

The principle is simple: a system shaping the spring and wire and can push the wireline freely anywhere in the work region. This provides the flexibility and functionality of the HX-series system as if The servo slides are going in three dimensions. The concept is an engineering marvel: cable, feed box, and quill not only rotate but also travel up and down, left and right, in and out, in both directions up to 6.3 inches! The impact is revolutionary: it is now feasible to make springs and wire shapes complicated or impractical previously. The computer is simpler to navigate than ever before, utilising the standard Windows program. Consider different possibilities by moving wireline to bend long springs and wire shapes without touching other equipment by wire, bend the wire in both directions with a circular center pin and, most notably, create several bends in the front leg after body coils are created.

BENEFITS

The HX system includes 8 independent servo sheets, rotary cable, rotary quill, running cable thread, and feed axes for metal. Optional axes provide up to 2 twin servo spinners with center pins revolving, 2 normal servo spinners, servo rotary tool keeper for initial tension regulation and double torsion springs, and broad wire servo cutter. The HX machines control all 21 servo motors with high speed and accuracy, without the use of homing sensors or limit switches, utilising Austria’s high-speed digital servos.

If you are looking for reliability, fast set-up, and high-speed development, the HX-series 21 axes CNC Spring Former is your pick. Dial NuCoil to see that the spring to wire companies are revolutionising the computers!