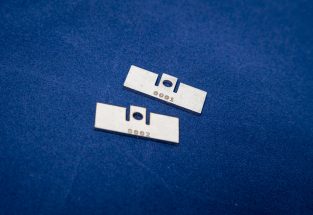

ENGRAVING AND MARKING

ENGRAVING:

This method is quick, as the material is removed with each pulse of the Laser Marking Machine. The depth of the marks is controlled by the number of times the laser beam is passing on the material.

It can be used on almost any kind of metal, plastic, wood, leather, or glass surface. You can get a lot of different engraved materials. Furthermore, it is more effective than traditional Fiber Laser Engraving Machines for small objects, such as jewelry.

There are also smaller chances to damage or deform the material. It can be used for many different applications, such as medical devices, automotive, and so on.

ANNEALING LASER MARKING:

Annealing marking refers to an oxidation process of applying heat to a surface material (without applying a high amount of aggression). This type of Laser Marking generally results in a solid black mark with a smooth finish, but based on the temperature at the surface of the mark, colors can also vary between shades of yellow, red, and green

This process is typically slower because the annealing relies solely on heat to bring carbon from the metal to the surface and make the markings. Once the metal is heated, you must also allow it to gradually cool.

Common metals used during the process of laser annealing include the following:

TITANIUM

STEEL

STAINLESS STEEL

IRON

In addition, this process can be used for a variety of industries.