LASER CUTTING AND MARKING

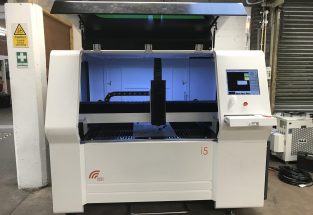

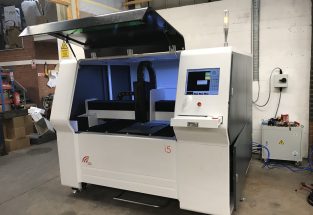

BODOR I5 LASER CUTTER

As Adwin specialize making a prototype for some of the world’s leading manufacturers so we decided that it would be beneficial for us to purchase our own Laser Cutting machine to help reduce the lead times for all of our customers.

Whilst manufacturing prototype parts you need to be able to make small adjustments to the design because of this investment we are now able to make alterations in minutes.

With a lot of options to go for we chose the Bodor, i5 Laser machine is because of its heavy bed which makes the machine more stable whilst cutting in comparison to other machines. The laser Machine also has a high-quality, electrical software control system which gives the Laser a more precise cut which is needed for some of the smaller parts we manufacture.

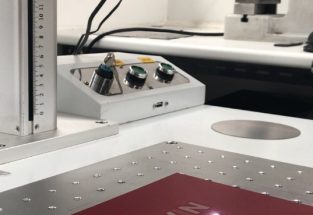

LASER MARKER

This laser engraving device is made up of a high-frequency beam produced from a light source. This beam is then intensified and guided through a set of spinning mirrors to a component to be marked on. The reaction occurring inside the marked material consists of 2 different processes:

- Engraving: A design is formed in the material’s first layers

- Marking: this renders a carbon coating clearly noticeable within the material

Fiber laser marking is commonly accepted as one of the most successful marking techniques and provides a range of solutions for every market. Our Laser Markers can engrave any of the parts that we produce either with part/batch numbers or individually permanently engrave a serial number or bar code / QR code that will be traceable back to the date of manufacture and batch of material etc. We will label, Mild Steel, Stainless Steel, Bronze Phosphorus, Copper, Aluminum, and Sterling Silver.

BENEFITS

The HX system includes 8 independent servo sheets, rotary cable, rotary quill, running cable thread, and feed axes for metal. Optional axes provide up to 2 twin servo spinners with center pins revolving, 2 normal servo spinners, servo rotary tool keeper for initial tension regulation and double torsion springs, and broad wire servo cutter. The HX machines control all 21 servo motors with high speed and accuracy, without the use of homing sensors or limit switches, utilising Austria’s high-speed digital servos.

If you are looking for reliability, fast set-up, and high-speed development, the HX-series 21 axes CNC Spring Former is your pick. Dial NuCoil to see that the spring to wire companies are revolutionising the computers!